The Comprehensive Guide To Glitter Heat Transfer Vinyl

Share

Glitter heat transfer vinyl is a vinyl material that incorporates heat transfer technology. It is widely used in personalized decoration of T-shirts, hats, sports products and other commodities, and is widely welcomed for its unique flash effect and durability. In this article you’ll learn all about what glitter heat transfer vinyl is, how to apply it, the pros and cons, how to customize it, and more.

Table of Contents

Introduction to Glitter Heat Transfer Vinyl

Introduction To Heat Transfer Technology

Before learning what glitter heat transfer vinyl is, you need to understand what heat transfer technology is. Heat transfer is a technology that uses heat energy combined with transfer media to transfer patterns or text to a substrate. Commonly used transfer media include vinyl.

Introduction To Vinyl

If you have no idea about vinyl, you also need to know what vinyl is. Vinyl is a material used to decorate clothing, bags, and other soft items. It is generally divided into two types: one is adhesive vinyl, the other is heat transfer vinyl (HTV for short), here we mainly talk about heat transfer vinyl.

Properties of Glitter Heat Transfer Vinyl

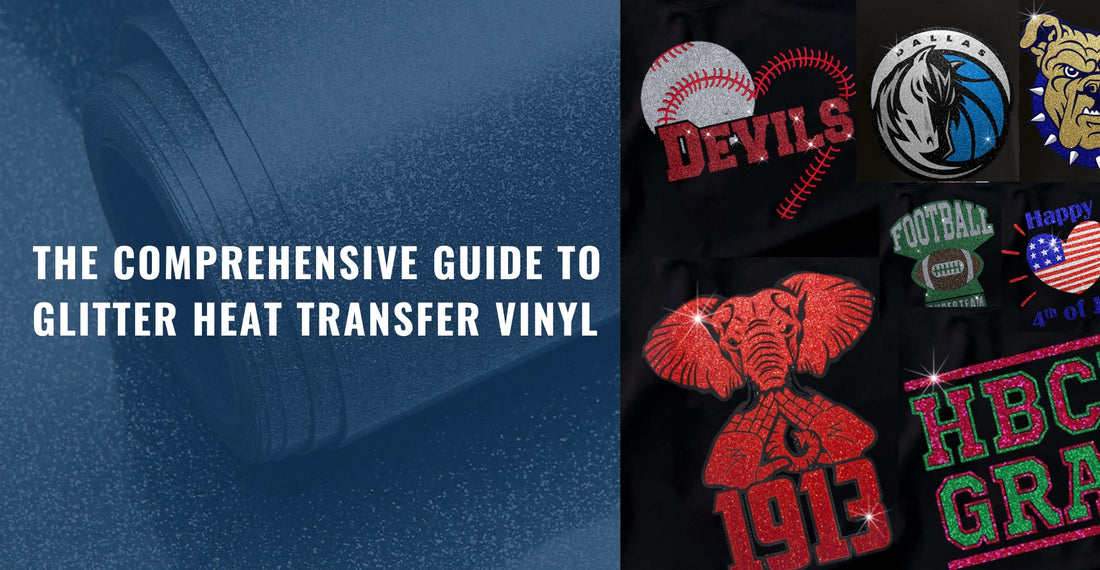

Glitter heat transfer vinyl is exactly what the name suggests... glittery heat transfer vinyl that adds a beautiful, shiny shine to your designs, increasing the visual appeal of your product. If you like eye-catching projects, glitter vinyl is definitely your choice.

Color Options

As with most heat transfer vinyl there are a variety of color options, at HYI we have over 50 colors in stock for you to choose from to easily match your design. click here to view stock colors.

Application Areas

- Personalized clothing: such as customized T-shirts, hats, etc.

- Sports products: such as sportswear, backpacks, etc.

- Outdoor Advertising: Used to create high-visibility warning signs and signage.

Process Flow

- Design: Use design software such as AI or CDR to create the pattern or logo into a production-ready file.

- Cutting and printing: Use a laser cutter to cut the pattern into the desired shape or print the designed pattern onto transfer media.

- Weeding: Remove excess vinyl from the cut design, leaving only the final design.

- Heat press transfer: Place the cut transfer medium on the substrate, and apply appropriate temperature and pressure through a heat press to complete the transfer.

Art Guidelines

- Positive Space:0.8mm

- Negative Space:1mm

- Color:50+ colors

- Font:Vectorized

- Whether to Mirror:Yes

- File Formats:Recommend PDF, , ESP, CDR,SVG or Ai format, or use PNG files with a resolution of 300 dpi and no background.Other formats such as JPEG, PSD or TIFF are also possible, but it is highly recommended that you review them to ensure they are feasible. These file types tend to be lower quality and may need to be adjusted for best results. If you have no art file, we offer free design for you.

- Tip:HYI provides one-stop free design service, you only need to send us the draft or reference drawing. You don't need to consider the details, let us handle everything for you.

Pressing Instructions

- Temperature control: Ensure that the temperature of the thermal transfer machine is controlled within a suitable range, generally 160-180℃/320℉-355℉.

- Pressure adjustment: Adjust the pressure according to the thickness of the fabric, generally 4-6bar/Medium pressure.

- Time control: Keep the pressure for about 15-20 seconds to ensure it is firmly fixed on the fabric.

- Applicable fabrics:cotton, polyester, blended.

- Peeling method:peel warm.

- Tip: It is recommended to perform a press test first, especially for fabrics with special coatings. For more press guides check out our guide to heat transfer processing methods.

Advantages and Disadvantages

Advantages

- Environmental protection: The material itself is environmentally friendly, non-toxic.

- Adaptable: suitable for most fabrics.

- Easy to apply: Easily transfer with just an iron or press

- Personalization: Each product can have a different design.

- Short lead time: Small batch orders have shorter lead times.

- Cost-effectiveness: Small batch production costs are relatively low.

- High-quality graphics:Ability to generate high-quality and complex graphics.HTV (iron-on vinyl) graphics can last a long time if done correctly, and your HTV won't fade or wash out after multiple washes.

- Detailed design: Printable glitter heat transfer vinyl to support more complex patterns and details

- Pressing on demand:No large inventory, flexible production according to order requirements.

Disadvantages

- High Cost: Cost is higher when produced in large quantities.

- Quality: Lower quality than silk screen printing.

- Requires specialized equipment: If you want to produce it yourself, you will need a vinyl cutter and heat press. While these are not expensive, they mean more expenses on your part and not everyone has the means, especially start-up enthusiasts. Some beginners interested in custom printing may find the upfront investment in equipment to be too expensive.

Customized Instructions

Customized Details

- Minimum order:10 pieces.

- Pre-production physical sample: available for fee.

- Stock sample:available for free.

- Digital proof:within 24 hours and no set up fee.

- Production time:2-3 days after order is placed.

- Tip:For price list, product catalog and more details please contact us.

Customization Process

- Inquiry:Send your designs, or information about your desired product (size, color, materials and quantity) to info@hyifashion.com.

- Layout & Quote:Our professional designers will create a layout for your design, sending you this with a quotation within 24 hours.

- Payment & Production:When you confirm you are happy with the layout, you will be sent an invoice.When your payment has been processed, production begins.

- Shipping:It’s that simple! Your order will then be shipped by UPS, DHL or FedEx, with delivery taking 2 to 3 business days.

Conclusion

As a unique personalized customized material, glitter heat transfer vinyl is not only decorative, practical and durable, but also has a wide range of market application prospects. As the market demand for personalization grows, having key information about it will help you capitalize on it and grow your business.

Are you ready to use it to customize your designs? Get started now! Also, if you have any questions or better experiences you'd like to share with us, feel free to leave a comment or send us an email.